Quality, safety, and customer satisfaction are the core values our injection molding services are founded on.

When appropriate, we do 100% inspection. In other cases, we work with you, our customer, to develop Axis Generation standards. Our return rate of less than 0.01 percent speaks to our attention to detail. We source all of our molds in the United States for superior quality and protection of intellectual property. This also shortens lead time, so we can get your custom injection molding product started and brought to market that much sooner. We handle both large and small runs with the same professionalism and efficiency, and we will always work within your tight schedule.

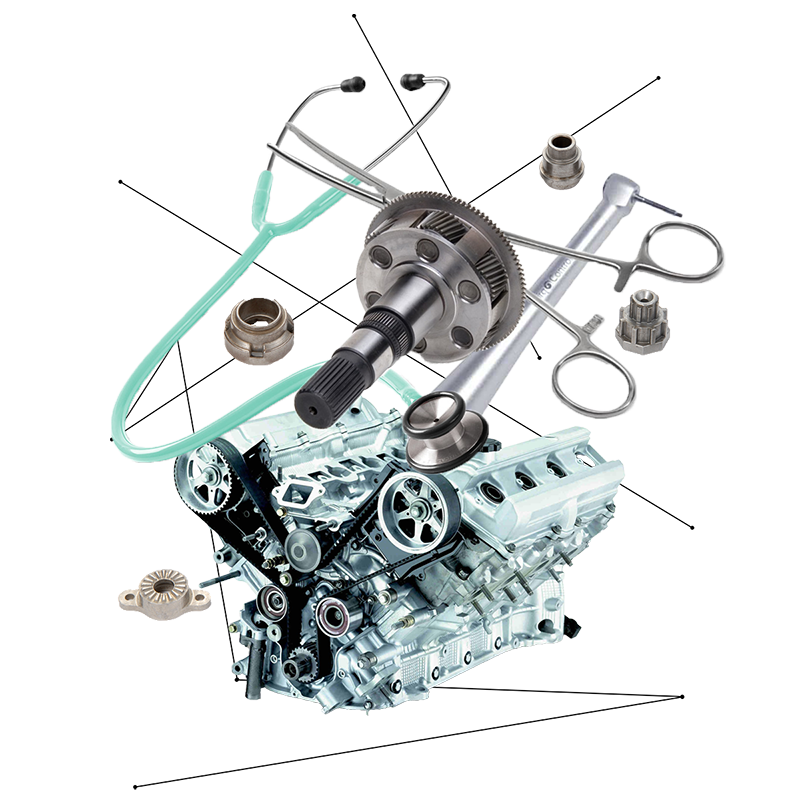

We will consult with you on materials, color integrity, durability, and texture to find the right match for your product, and will source it from a network of reputable material suppliers, Molding is a trusted leader in silicone injection molding for high-end consumer and life science applications. We specialize in products for women and babies, including nursing pads, and food-safe silicone pacifiers, teethers and dinnerware. We offer one-of-a-kind silicone expertise and have a strong network within the materials supplier community.

Before production, our expert engineers will provide you with a detailed set of specifications for review. During production, your components will undergo our rigorous quality assurance process, ensuring manufacturing at the highest possible standards. In fact, we are able to boast one of the lowest defect rates in the industry. Lastly, we will develop the optimal packaging solution to keep your shipping and transportation costs as low as possible.