CNC Laser Welding

Axis Generation MICROSCOPIC Hi-Precision Automatic CNC Laser Welding

Laser Welding is ideal for applications requiring pin-point accuracy at high production rates. It’s non-contact, doesn’t require a vacuum, and is excellent for joining thin materials and small components.

Application Advantages of Laser Welding

Deep Weld Penetration

Weld penetration can be closely controlled, and ranges from a minuscule 0.005 inches to a depth of up to 0.25 inches.

Micro Part Welding

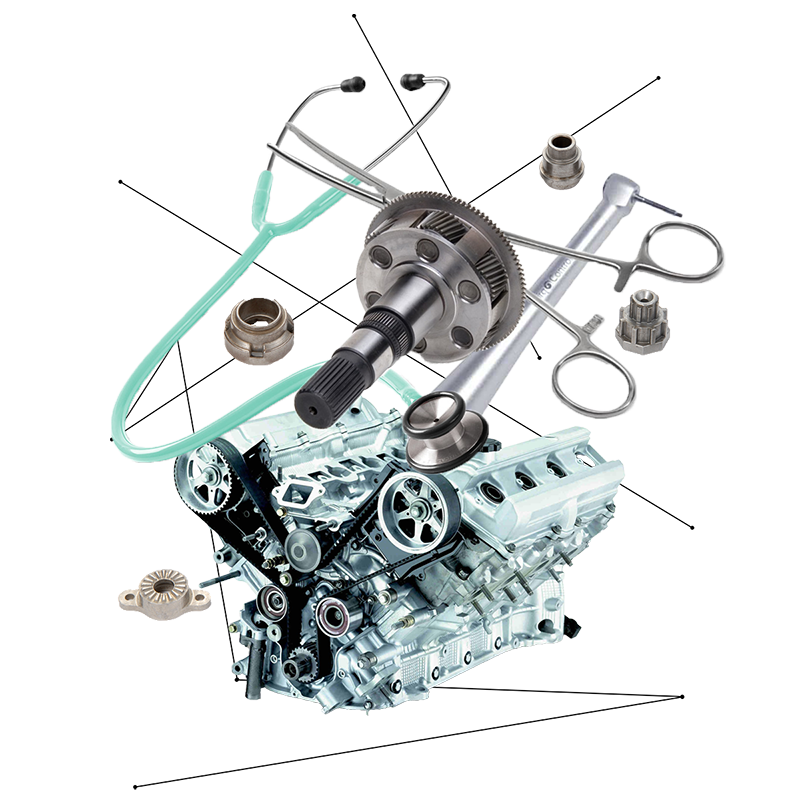

Given the small and precise nature of the laser beam, very small and very thin materials can be easily joined. This includes welding of foils, stents, sensor diaphragms, and surgical instruments.

Low Heat

Pulsed lasers can minimize the amount of heat applied to a part, thus helping to keep critical electronics and other components cool.

Dissimilar and Crack Sensitive Material Welding

Laser welding can join dissimilar materials and also crack sensitive materials.

No Vacuum Requirement

Laser welding does not require the parts to be in a vacuum, which can result in faster production cycles.

High Feed Rates

Laser welding can occur at feed rates up to 200 inches per minute, which is much faster than conventional welding processes such as MIG and TIG. High feed rates mean faster welds and lower costs.