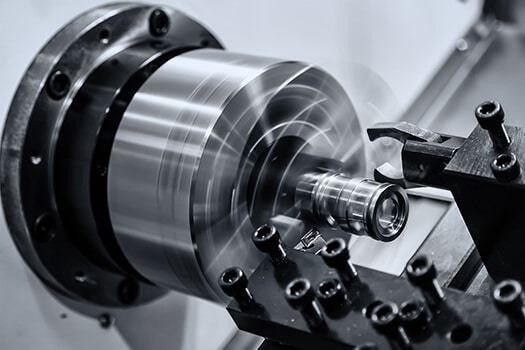

CNC Turning

How CNC Lathe Works

CNC turning (also known as CNC lathes) is a subtractive manufacturing process in which a stationary cutting tool removes material by making contact with the spinning workpiece to create the desired shape.

During processing, a blank bar of stock material is held in the chuck of the spindle and rotated with the spindle. Extreme precision and repeatability can be achieved under the control of computer instructions for the movement of the machinery.

When CNC turning rotates the workpiece in a chuck, it’s generally to create round or tubular shapes and achieve far more accurate rounded surfaces than CNC Milling or other machining processes.

- Chuck: Fixes the bar of stock material for machining

- SPINDLE Rotates the chuck across axes for material forming.

- Turret: Moves the stock bar in line with the computer-aided manufacturing (CAM) blueprint or computer-aided design CAD..

- Interface: Provides options for the operator to control and use the turning centers.