Contact

AXIS GENERATION CORPORATION, 61-B, Liaqat Ali Road, Industrial Estate, 51310 Sialkot Pakistan.

+92 331 3177777

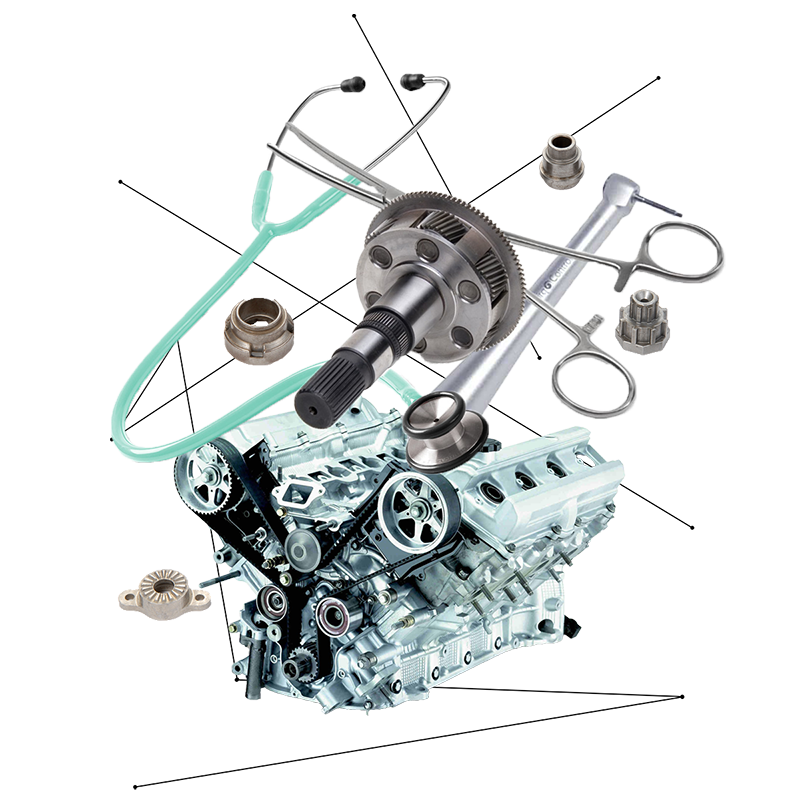

This section delves into the complex but fascinating process of 3-axis machining.

In 3-axis machining, the cutting tool moves along the three axes – X, Y, and Z.

The X and Y axes represent the horizontal plane, while the Z axis signifies vertical movement.

The combined motion in these three axes allows the CNC machine to accurately and efficiently remove material from the workpiece, giving it a desired shape.

CNC machines play an essential role in 3-axis machining. These machines, equipped with automated cutting tools, are capable of executing complex machining operations with high accuracy and speed.

Additionally, the CNC milling machine’s spindle’s rotation enhances the cutting tool’s ability to create precise geometric shapes.

A key component of the 3-axis machining process is the milling machine. It is this machine’s extraordinary precision and range of movement that enable it to craft complex geometries from raw materials. The greater accuracy of these machines ensures that even the most intricate mechanical components can be machined to exact specifications.

When it comes to 3-axis machining, the kind of CNC machine used is critical. For instance, a 3-axis CNC machine is ideal for tasks that involve material removal in three planes.

On the other hand, a 5-axis CNC machine offers even more capabilities, including the ability to rotate the cutting tool or workpiece around additional axes (the A and B axes), thereby enabling machining of more complex parts.

Stay updated on all of our latest range!

Copyright © 2024 Axis Gen Corporation, All rights reserved.

Design & Developed By sial web