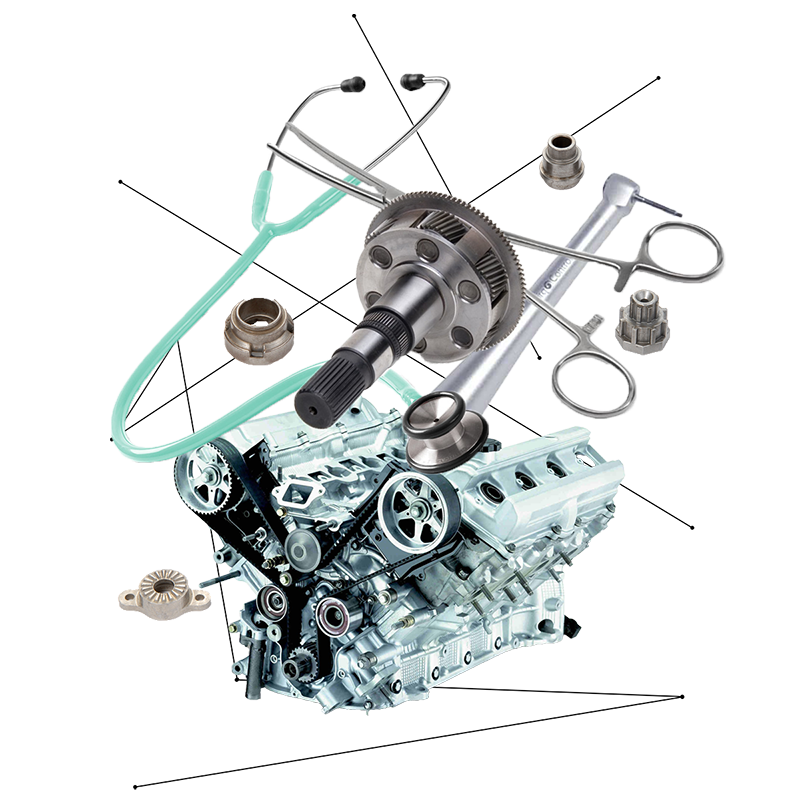

Advanced Plating Technologies provides a diversity of passivation and cleaning services across a range of industries. Services include precision medical-grade cleaning and precision passivation as well as commercial and AAA (Acid-Alkaline-Acid) passivation in both nitric and citric acid. Additionally, Ultrasonic cleaning and vapor degreasing are available as cleaning cycles as well as pre-treatment to subsequent plating services.

Passivation of Stainless Steel

Simply put, passivation is a process that makes corrosion resistant alloys corrosion resistant. The process utilizes oxidizing acids to remove free iron from the surface of stainless steel that is present due to preceding forming and cutting manufacturing processes. In addition to removing the free iron, a thin, dense oxide barrier is formed to provide a barrier to further corrosion. Advanced Plating Technologies offers high volume, citric and nitric commercial passivation services to ASTM A967, AMS 2700, and QQ-P-35 including hard-to-source variants that require sodium dichromate and heated nitric acid. AAA methods that require an alkaline-acid-alkaline sequence can also be provided.

Passivation of Titanium and Medical-Grade Alloys

Advanced Plating Technologies provides precision, medical-grade passivation of titanium and other medical-specific alloys including cobalt-chrome, cobalt-nickel, tantalum, MP35N and 316LVM stainless steel to ASTM F86, ASTM A380 and ASTM A967 utilizing a dedicated medical passivation line. APT’s precision line utilizes up to seven stages of sonication including ultrasonic cleaning, multi-stage hot deionized ultrasonic water rinses, ultrasonic passivation and a final sonic IPA if required. Tooling, chemistry and process controls are in place to handle small to micro components found within the medical and dental industries.

Ultrasonic CleaningUltrasonic cleaning removes chips and cutting oils from machining. This process also allows for interior cavities and blind holes to be thoroughly cleaned more effectively than other standard cleaning methods. Advanced Plating Technologies is able to custom match solvents and cleaners to ensure the best possible cleaning outcome for an application. Similar to vapor degreasing, this process can be paired with different cleaning processes such as electrocleaning and vapor degreasing.