Injection Molding

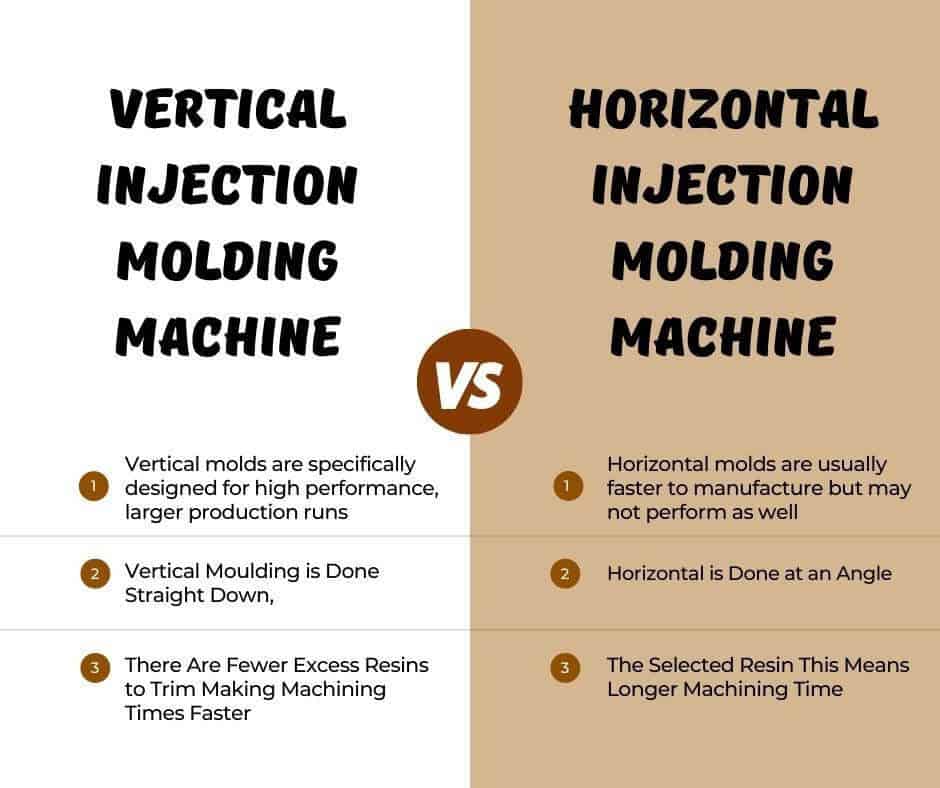

In horizontal injection molding, the mold opens and closes along a horizontal axis. Due to this configuration, consistent, correct injection pressure is required to fill the mold cavities and help ensure proper packing and cooling.

To make a plastic product which would satisfy the expectations of consumers, the suitable production process cannot be ignored. Generally, customers in injection molding industries for years are equipped to judge and select by themselves suitable injection molding machines that fit them. But under certain circumstances, customers may need the assistance of the manufacturer to decide which specifications will meet their needs.

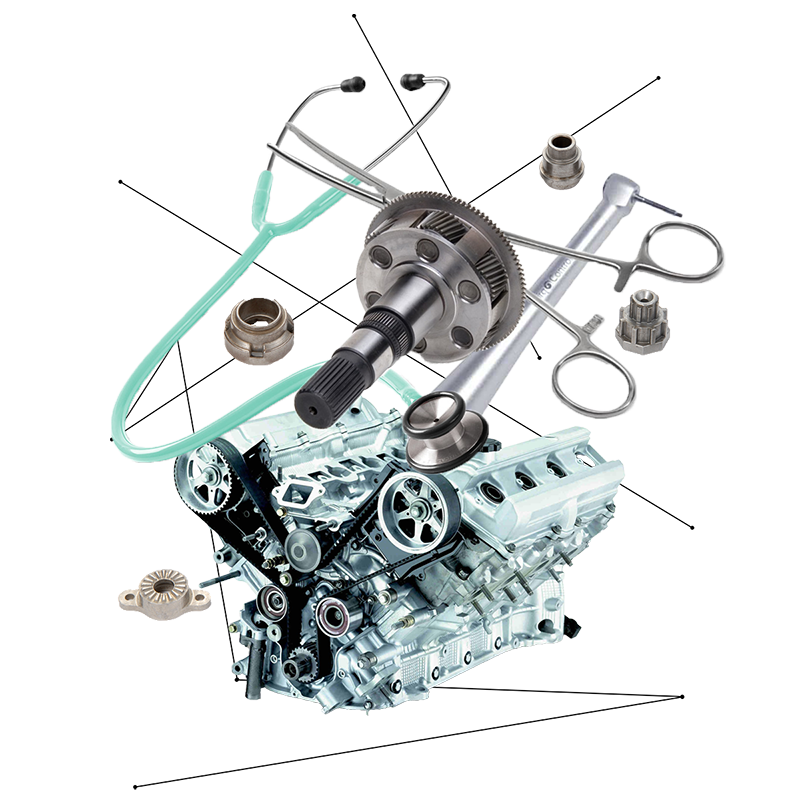

Sometimes, they may ask if the machines of the manufacturer could produce the products they have in mind, which they merely have a concept or sample, or they would ask which model is suitable. Also, some of the products may need special devices, such as accumulator, close loops, and injection compression, to match with the selected unit to manufacture their products efficiently. Hence, it is of vital importance to determine what type/model of the machine will serve their needs best. The following is information for your reference in making a decision.

Horizontal VS Vertical Injection Molding

The Injection Molding can be generally separated into two types by opening and closing direction of the mold clamping unit: horizontal and vertical. Both Vertical and Horizontal Injection Molding operate in the same manner, injection molten resin into an injection mold, hold the mold together to allow the part to harden, open the mold and then eject the parts